Taghapoon is the trade name for Sodium Lauryl Ether Sulfate 70%, which is a semi-transparent, white to yellowish paste-like chemical substance. It belongs to the family of alkyl ether sulfates and is classified as an anionic surfactant. This substance is produced by the combination of a fatty alcohol such as coconut oil with ethylene oxide, followed by sulfonation.

Currently, due to its numerous applications, the export of Taghapoon from Iran to other countries is thriving. Therefore, in the following, we will introduce this substance and its applications in various industries.

Taghapoon, also known as Sodium Lauryl Ether Sulfate, is widely used in cleaning products to remove fats and dissolve easily in water with high foaming. This category of substances does not require high temperature and agitation and can be incorporated into formulations by adding other materials.

Taghapoon is one of the most common raw materials in the cosmetics and pharmaceutical industries and is used in the production of most commercial detergents such as dishwashing liquid and industrial cleaners (car wash, floor cleaners, and oil removers), as well as in more than 90% of personal care and body wash products such as toothpaste, soap, shampoo, cream, and lotion, in both liquid and non-liquid forms. This substance is used as a surfactant, emulsifier, and cleansing agent to remove fats and sticky substances. Its usage rate in the final product is between 10 to 15 percent. Taghapoon has a mild odor, and manufacturers produce and supply it in concentrations of 30 and 70 percent.

Taghapoon can naturally irritate the skin and cause dryness. Therefore, it should be combined with other anionic, amphoteric, and nonionic surfactants to achieve the desired level of detergent and cleaning quality. To export Taghapoon, the best quality should be obtained. Therefore, in the following, we will introduce you to the best Taghapoon supplier.

As Sodium Lauryl Ether Sulfate or Taghapoon has many applications in the production of cleaning products, many manufacturers are looking to buy this chemical substance. Raag Trading Company is one of the best suppliers of Taghapoon in high volume. If you intend to export Taghapoon or are looking to buy high-quality and cost-effective Taghapoon for export, you can contact Raag Trading Company through their website, in person, or by phone to speak with their sales team.

The price of 70% Sodium Lauryl Ether Sulfate varies depending on the quality, packaging, demand, currency exchange rates, and other factors. Therefore, if you intend to export Taghapoon or Sodium Lauryl Ether Sulfate 70%, it is advisable to contact Raag Trading Company’s sales team to inquire about the current Taghapoon price. Raag Trading Company offers the most suitable price for Taghapoon when purchasing Sodium Lauryl Ether Sulfate.

Raag Trading Company is a reliable option for buying and selling Taghapoon for export, providing high-quality chemicals and raw materials for cleaning products. If you intend to buy or export Taghapoon to other countries, you can contact Raag Trading Company’s sales team and benefit from their guidance.

Individuals who intend to export Taghapoon can contact Raag Trading Company to place an order for Taghapoon or 70% Sodium Lauryl Ether Sulfate. This company can provide Taghapoon in large volumes for export or bulk purchases with the best and highest quality chemical substances from reputable manufacturers.

Taghapoon N70 is a sodium lauryl sulfate ether which is commonly used in transparent and pearly products with medium to high viscosity and in cleaning products. Taghapoon is a highly active sulfate ether produced from a medium-chain fatty alcohol and contains an average of 2 moles of ethylene oxide with maximum control of unintended byproducts, including odor-causing products. Taghapoon N70 is a highly concentrated sodium lauryl ether sulfate obtained from natural fatty alcohols. Due to its high surfactant content, Taghapoon is particularly suitable for very thick final products or for raw materials with lower water content if needed. Accordingly, the viscosity of diluted Texapon solutions containing approximately 5 to 28% surfactant can be easily increased to the desired amount. Other anions in it include sodium lauryl sulfate and sodium miristyl sulfate.

SLES or Taghapoon paste acts as a foaming, cleaning, and moisturizing agent. Often, cleaning products contain 30 to 70% Taghapoon paste. Taghapoon N70 is a paste-like substance with high viscosity and a clear appearance. Because this product contains salt, its viscosity decreases after dilution. By increasing NaCl and alkylamide, the viscosity of this mixture can be controlled. The N70 type of this product has the highest concentration of SLES produced in the process of ethoxylation of dodecyl alcohol and is more popular in Taghapoon exports.

The market and export of Taghapoon are mainly growing due to increased consumer awareness of personal hygiene and cleanliness. However, in recent years, concerns about health risks associated with sodium lauryl ether sulfate have arisen, leading in some cases to the replacement of this substance with other organic and biological materials in developed countries. However, its easy availability, cost-effectiveness, and good foaming properties have turned it into a lucrative additive for personal care product manufacturers. Therefore, extensive research has been conducted on its potential hazards. Research by the US Food and Drug Administration (FDA) has shown that the use of this substance is safe for consumers. The Australian Department of Health and Chemical Industries has also stated that this substance does not react with DNA. This substance and its derivatives break down the skin’s moisture barrier and allow other chemicals to easily penetrate into the subcutaneous tissue.

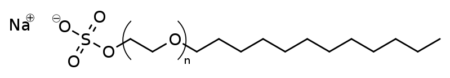

Taghapoon is an organic member of the sulfur-containing compound group with the formula CH3(CH2)11(OCH2CH2)nOSO3Na. N represents the number of ethoxy groups. For a more accurate description, it should be said that the chemical structure of these substances is formed in such a way that it consists of two parts: Hydrophobic and Hydrophilic. The hydrophobic part is made up of an organic chain insoluble in water and other polar solvents but soluble in nonpolar solvents and organic compounds, while the hydrophilic part, unlike the hydrophobic part, is soluble in polar solvents, including water. For more details on the best type of this product for Taghapoon exports, consult with experts at Raag.

Most of the dirt and stains that accumulate on clothing, dishes, the human body, kitchen surfaces, and similar items in the human living environment are created by organic compounds such as fats, proteins, and hydrocarbon compounds such as cellulose and starch. Even many types of pollution of non-organic origin such as dust and car exhaust adhere to the human body and clothing through these compounds.

As we know, organic compounds are not soluble in water, and therefore, removing them from the human body and other equipment used in daily life is not possible with pure water alone. In other words, if the process of dissolving in a solvent such as water does not occur, the dirt will not be separated from the desired surfaces, and the cleaning process will not be achieved.

In Taghapoon exports, quality comes first. The cleaning power of Taghapoon is very important. Surfactants with the ability to simultaneously dissolve in water and the ability to dissolve organic dirt in themselves can separate organic compounds from surfaces and prevent their reattachment to cleaned surfaces while suspended in water, allowing the cleaning and dirt removal process to occur.

The mechanism of surfactants occurs through reducing the surface tension on the surfaces of water and air and also between organic matter and surfaces to be cleaned. By reducing surface tension in the two target areas, it causes organic matter to be lifted off the surfaces and easily submerged in water. Of course, surfactants also have other properties such as emulsification, foaming, coagulation, and disinfection.

Surfactants are divided into four categories, anionic, cationic, nonionic, and amphoteric, based on their type of electrical charge in their hydrophilic part. Depending on the nature and expected performance of a detergent product and based on the opinions of formulation experts in research and development laboratories, each of these surfactants is used separately or in combination.

The most widely used surfactants in household cleaning products belong to the anionic group. In the formulation of cleaning products, anionic surfactants, which play the main role in cleaning, are usually used alongside other surfactants as a helper or modifier to adjust their properties.

Therefore, in the formulation of cleaning products, various useful raw materials, including two or three types of surfactants, are used to achieve various properties such as foaming, shine, softness, and prevention of re-deposition on surfaces, as well as Taghapoon’s cleaning and protective properties for skin, clothing, and washing equipment such as washing machines.

The majority of surfactants used in cleaning products belong to anionic surfactants, which have a negatively charged polar head. One of the most important anionic surfactants is Taghapoon, which is a sulfonated fatty alcohol derived from plant-derived fatty alcohols. To achieve surfactant properties, the process of sulfonation, which involves introducing gaseous SO3 onto the organic chain, is necessary. This process is carried out in a unit called a sulfonation unit. By introducing SO3 gas onto the organic part, the polarity of the new compound increases, which enhances its solubility in polar solvents such as water. The process is followed by neutralization with an alkali such as sodium hydroxide or caustic soda, which also affects the polarity and ultimately the efficiency of the surfactant. The resulting product is the best option for exporting Taghapoon.

Many manufacturers of cleaning products pay attention to the formulation and production process of Taghapoon. Therefore, it is recommended to become familiar with the production process of this substance for its exportation. In summary, in the sulfonation process, the dry air unit provides the required air for combining with sulfur. This air should be completely dry and have a dew point of minus 80 degrees Celsius. This is achieved with equipment such as a blower, an ethylene glycol tower, a chiller, and a silica gel tower. Then, in another part of the plant, sulfur melts in a sulfur furnace and combines with dry air (burns) to produce SO2 gas.

SO2 gas is then fed into special converters, equipped with specific catalysts, which combine with oxygen in the converter to produce SO3 gas. This gas is then combined with ethoxylated fatty alcohol in special reactors to ultimately produce lauric acid. Some of the SO2 and SO3 gases do not enter into the reaction with the organic chain and are trapped by an electrostatic filter and a scrubber tower filled with lime to prevent them from entering the environment. The lauric acid is then neutralized with lime and passes through a pH stabilizer and deodorizer before being sent to storage tanks.

1- Avoid contact with eyes and skin with Taghapoon or sodium lauryl ether sulfate, and if in contact, wash it and seek medical attention.

2- When working with chemical substances such as Taghapoon, use a mask, gloves, and safety glasses.

3- Avoid swallowing and inhaling Taghapoon.

4- Keep Taghapoon out of the reach of children and ordinary people.

Due to the use of this product in various industries, the export of Taghapoon as one of the main components of detergents has a good growth trend. Below are some of its most important uses:

This substance is an emulsifying, foaming, dissolving, and cleaning agent used in the cleaning and food industries and is an anionic surfactant in the production of shampoo. It is used in most commercial cleaning products such as dishwashing liquid and industrial cleaners (floor cleaners, car wash liquid, oil remover) and in more than 90% of body cleaning products such as toothpaste, soap, shampoo, cream and lotion, floor cleaner liquid, as well as raw materials for cosmetics, hygiene, and medicine.

As a cleaning agent, it is used in most personal and body hygiene products. It has good foaming properties but is lightweight and does not have a creamy texture, and is lost in the presence of fats. It has a stimulating effect on the skin and damages the skin’s two-layer fat structure. Therefore, when accompanied by other anionic, amphoteric, and non-ionic surfactants, the quality and amount of foam and cleaning on the surface are provided at an acceptable level. The chemical properties of this substance are easily usable in neutral pH formulas, and it has no effect on viscosity and other properties of the color formula.

Storage time: It can be stored for up to one year under normal conditions. It is recommended to protect it from freezing.

Taghapoon is packaged and transported in 220-liter plastic drums coated with nylon inside. Raag company registers your order for exporting the best Taghapoon in completely standard and hygienic packaging and delivers it to the factory door.